Saturday, March 5, 2016

Protective Shoring Systems and their Various Names

Protective shoring systems are techniques of securing employees from cave-ins of product

that can fall or roll right into an excavation, or from the collapse of nearby structures. If an excavation is much less compared to 5 feet deep, OSHA does not need a protective systems unless the proficient individual sees indicators of a possible collapse.

(It is essential to bear in mind that a wall collapse in a trench four and also 1/2 feet deep can still have major results!) For trenches between 5 feet and even 20 feet deep, shoring as well as sheeting, shielding, sloping and also benching are all acceptable safety steps.

It is up to the organizers of the design job as well as the experienced individual on website to identify which systems are most proper. If an excavation is higher than 20 feet deep, a signed up professional engineer must create the protective system.

Shoring systems are frameworks of hardwood, mechanical, or hydraulic systems that sustain the sides of an excavation and also which are designed to avoid cave-ins.

Sheeting is a kind of shoring system that keeps the earth ready. It could be

driven into the ground or operate in conjunction with a shoring system. Driven sheeting is

most frequently used for excavations open for lengthy periods of time. An additional kind of

sheeting, where layers or shoring quality plywood is utilized along with strutted

systems such as hydraulic or hardwood shorting. These strutted systems are also referred to as energetic systems. One of the most often made use of strutted system entails aluminum

hydraulic shores which are light-weight, re-usable and mounted and even eliminated completely

from above ground.

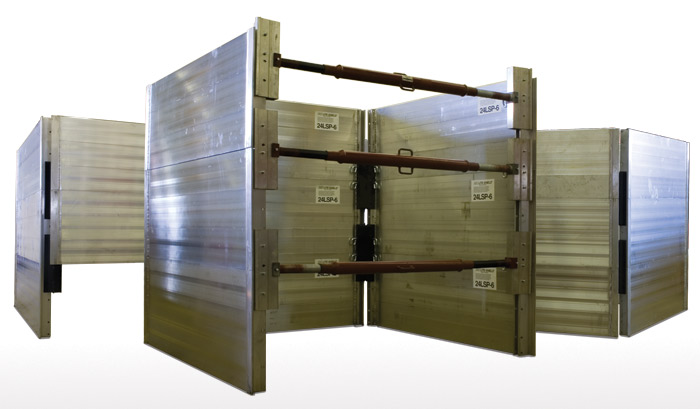

A shield, commonly described a trench box is one more usual safety

system made use of by professionals, an outstanding option when continuous straight installations are contemplated. It's put in the trench and also dragged together with the development of the work.

A few important points concerning guards:

Employees must be out of the box and even over ground when the guard is being moved.

You could be caught between the relocating box and stationaried object(s);.

The top of the guard should expand at the very least eighteen (18) inches over the degree of anymaterials that might cave or roll right into the trench;.

Some shields are made to be piled, one on top of another. The forces of a cave-in.

could essentially press a box sideways, triggering a crushing threat. After a box is placed.

for the job, the voids between the box and even the trench wall surface ought to be loaded with.

excavated product to prevent displacement brought on by a cave-in.

Sloping and benching are an additional method of protecting employees from.

collapse hazards. Sloping is an approach of digging deep into in which the walls of an excavation.

are laid back to an "angle of repose" suitable to the sort of soil.

Subscribe to:

Post Comments (Atom)

I have been looking for products that help in preventing the cave-in from happening and wanted someone to refer me a good vendor or dealer. The quality has always been very important for me to and local companies didn’t guarantee that. Through your blog information I contacted Trench Pro which guided me about hydraulic shoring products which fulfilled my requirements! All of the Hydraulic Shoring Products can be used in areas with crossing utilities, spot repairs, tight situations, and sites that a larger machine just can’t get too. Trench Pro has many options for these products in their stock. I purchased my Hydraulic shoring products simply with Trench Pro. Thank You for your Blog!

ReplyDeleteTrench pro provided Trench Safety Products to Rent. For me, it was such a productive and economical deal. I regularly rent trench safety equipment from Trench Pro, and they never disappoint me.

ReplyDeleteI would like to say that this blog really convinced me to do it! Thanks, very good post. shoring box

ReplyDelete